Objective

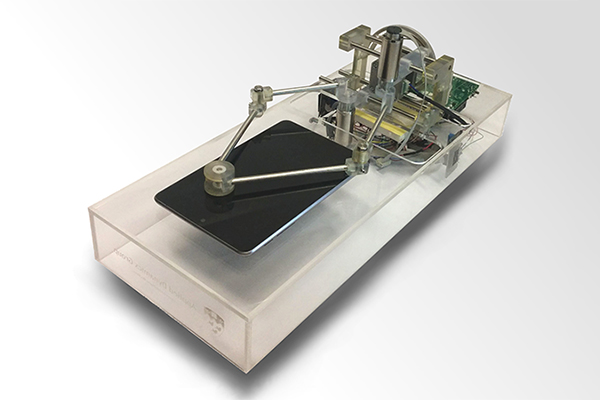

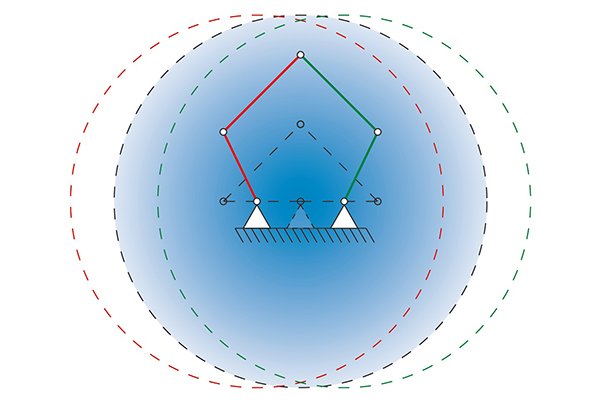

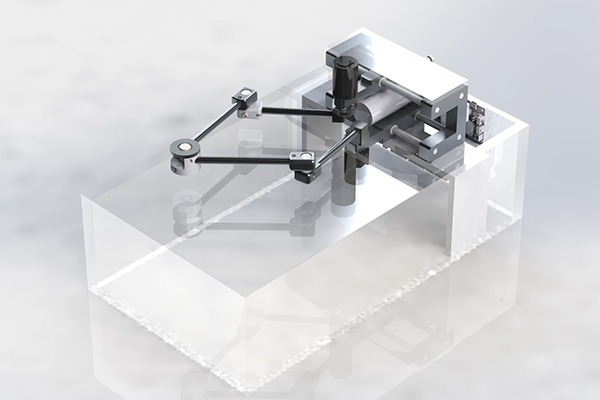

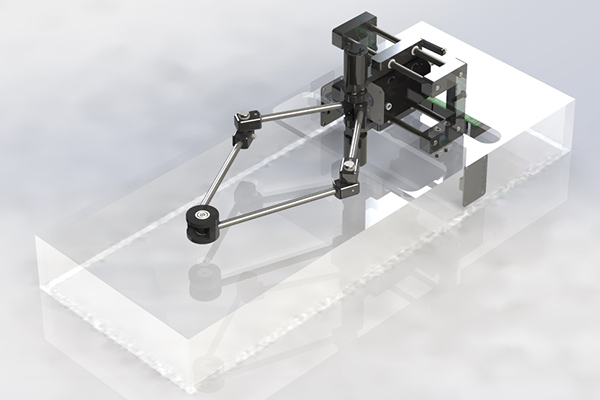

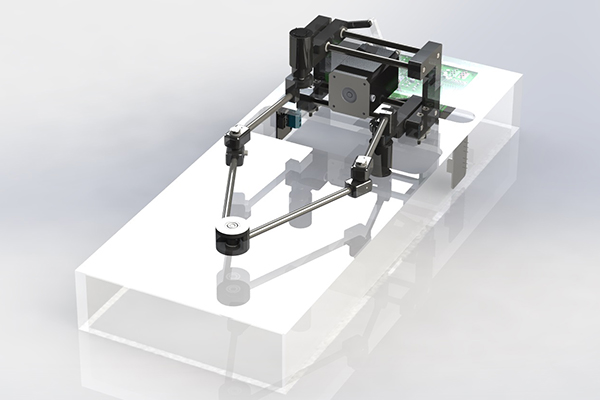

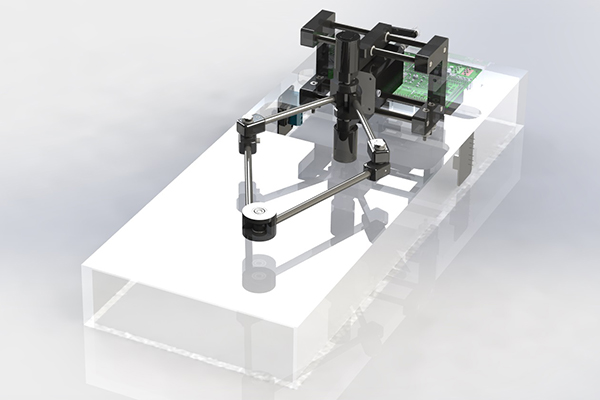

To design and build a working prototype of a modular desktop haptic device. The device consists of a 5R parallel planar mechanism to achieve planar, 2 degree-of-freedom (DOF) motion. A third, redundant DOF is implemented to reconfigure the active base joints changing dynamic and workspace properties of the mechanism to use for specific tasks.

The end-effector (the joint that connects the red and green links in the illustration) is the point with which a human interacts. The rest of the mechanism is used to generate forces at that point and read its position.

Iterative Design Process

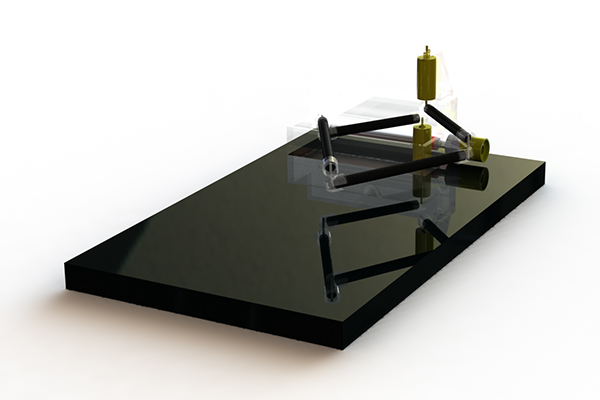

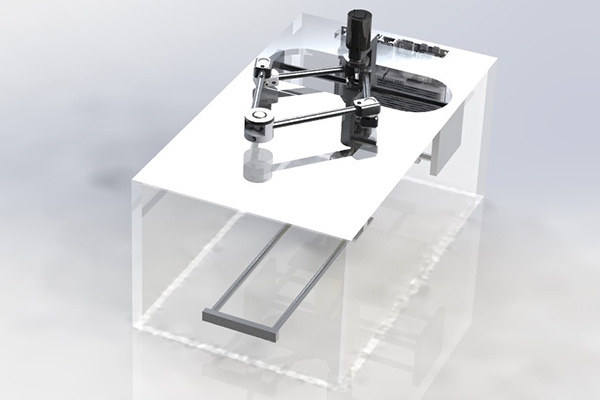

The initial design specifications were very open ended and therefore several desired attributes were realized at different iterations of the design. Lab-wide design reviews resulted in the discovery of new requirements, leading to more than ten different design revisions. The revisions with the greatest changes are depicted here.

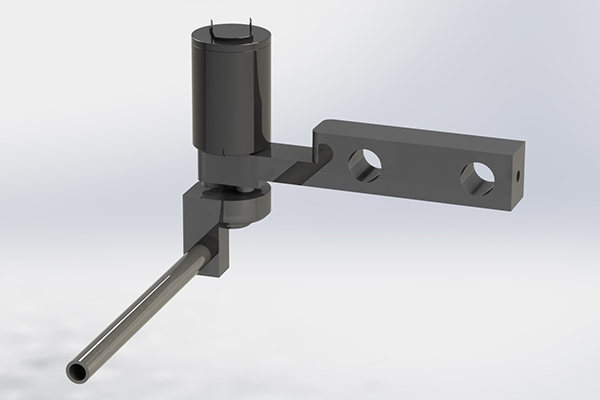

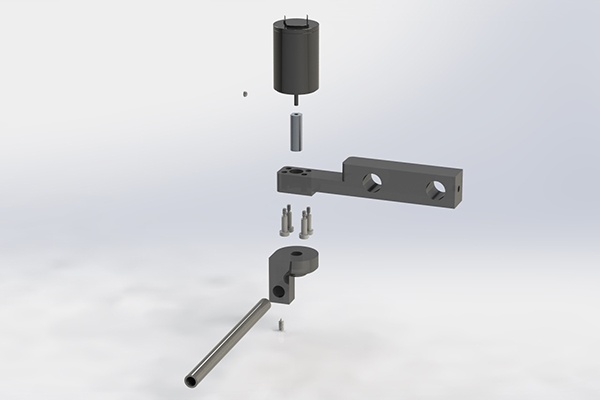

Base Joint Reconfiguration

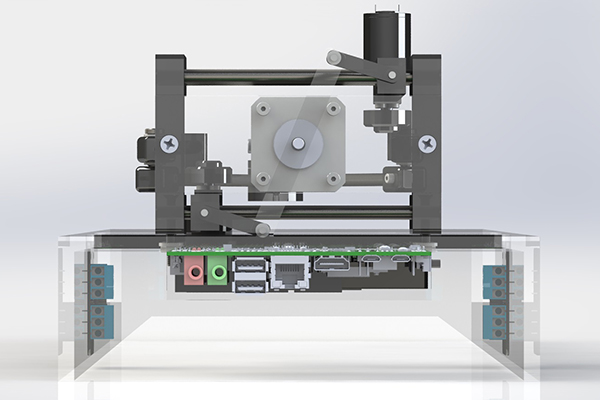

The base joints are reconfigured simultaneously and symmetrically using a piston-crank-arm mechanism driven by a stepper motor.

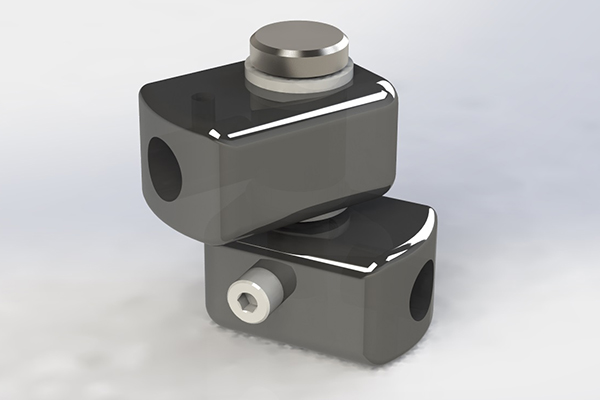

Actuated Joints

The base joints are directly actuated by a DC motor with a D-profile hub. Other reconfiguration options are also being explored.

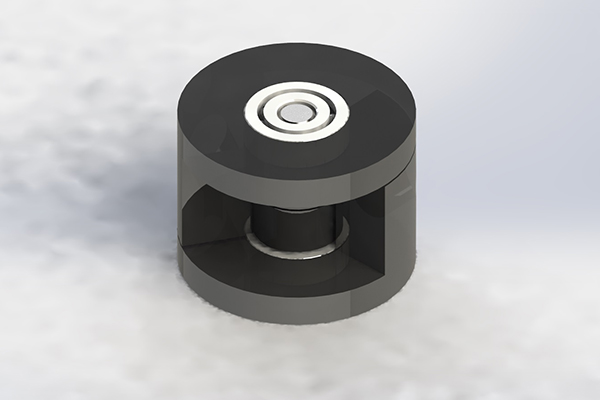

Passive Joints

The passive joints use bearings and a pin to assure that any "play" is minimized.

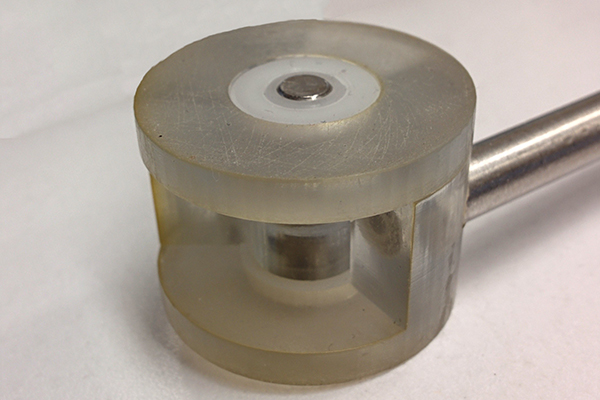

Rapid Prototyped Parts

The project makes use of SLA rapid prototyping to minimize cost of manufacturing for a number of small parts.

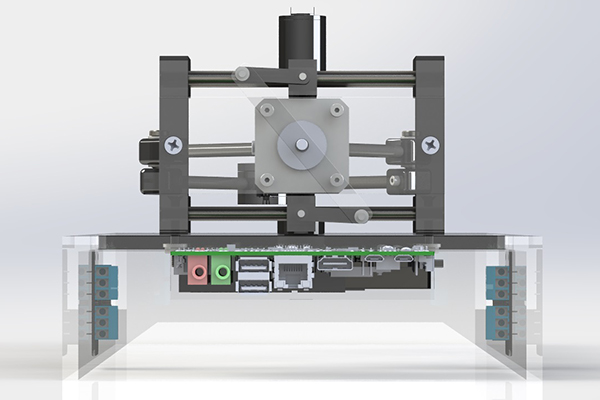

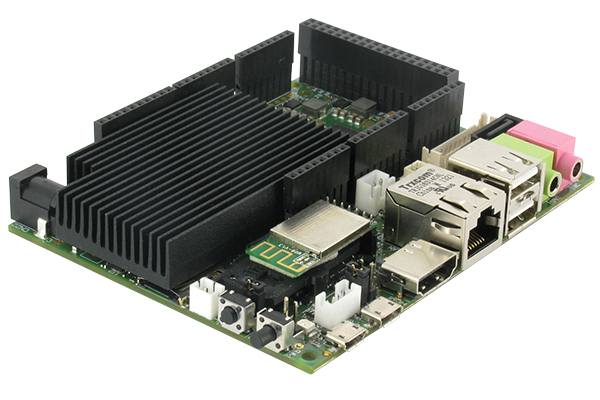

Control System

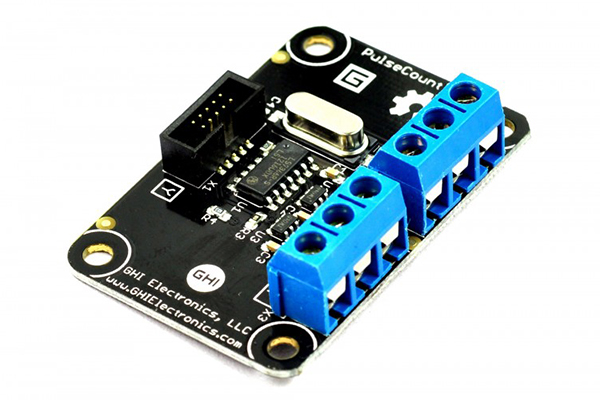

The control system utilizes the UDOO multi-processor single-board-computer making use of the Arduino API (see UDOO website for details). Position is determined using quadrature encoders on the base joint actuators and decoded using LS7366 32-bit CMOS counters on two GHI Pulse Count Modules which communicate via SPI with the UDOO board.

Current Project Status

The project was demonstrated at the IEEE World Haptics Conference in June 2015. Here is a temporary page explaining the details of the system architecture. You can also view a video of the demo in action.